Electronic products have invaded our lives invisibly, and we are indeed inseparable from convenient electronic products. Now many people open their eyes and pick up their mobile phones, turn on the speakers, and start a new day. But do you know? We use electronic products every day, but few people care about the heat dissipation of electronic products. The heat dissipation of electronic products is very important. If the heat dissipation of electronic products is not good, it is very likely to cause electronic product explosions, damage to electronic product parts, and so on. Next, we will talk about why electronic profile radiators use 6063 aluminum profiles as radiators.

6063 aluminum heat sink

Excellent Thermal Conductivity

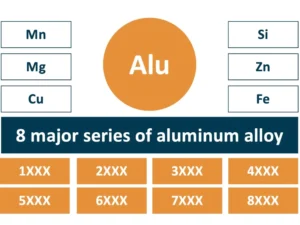

6063 aluminum alloy has strong thermal conductivity and can help electronic products dissipate heat very well. As for the material of aluminum profile radiator, each material has different thermal conductivity. They are arranged from high to low according to thermal conductivity, namely silver, copper, aluminum, and steel. However, it would be too expensive to use silver as a radiator, so the best solution is to use copper. Although aluminum is much cheaper, its thermal conductivity is obviously not as good as copper (only about 50% of copper).

The commonly used materials for aluminum profile radiators are copper and aluminum alloy, each of which has its own advantages and disadvantages. Copper has good thermal conductivity, but it is expensive, difficult to process, too heavy, has a small heat capacity, and is easy to oxidize. Pure aluminum is too soft and cannot be used directly. Aluminum alloy is used to provide sufficient hardness. The advantages of aluminum alloy are low price and light weight, but the thermal conductivity is much worse than copper. Some radiators take their own strengths and embed a copper plate on the base of the aluminum alloy radiator. It can take into account the price issue and ensure the quality of heat dissipation.

Superior Extrudability

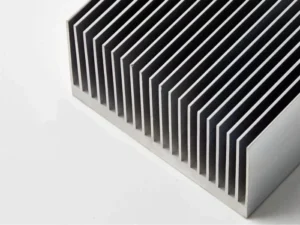

6063 aluminum is highly extrudable, allowing for the creation of complex, thin-walled shapes with high surface area, which increases heat dissipation. Its extrudability makes it easy to design heat sinks with intricate fin patterns, maximizing surface area.

Smooth Surface Finish

6063 aluminum radiators can undergo various surface treatments, with a wide variety of patterns and colors, and no solder joints. They are highly decorative, beautiful and durable, and can meet people’s personalized requirements. Zhigao Industry can also process sandblasting, drawing, polishing, surface anodizing, hard oxidation and other processing techniques to produce more beautiful aluminum profile radiators.

For example, 6063 aluminum produces a smooth, aesthetically pleasing surface finish that is well-suited to anodizing. Anodizing not only improves corrosion resistance but also enhances thermal emissivity, further optimizing heat dissipation.

Good Corrosion Resistance

Heat sinks are often exposed to air, moisture, or other potentially corrosive environments, and 6063 aluminum naturally resists corrosion. This extends the lifespan of the heat sink and ensures consistent performance over time.

Lightweight and Strong

6063 aluminum offers a good balance of strength and lightness, making it ideal for applications where weight reduction is important, such as in consumer electronics, automotive, and aerospace industries.

In summary, 6063 aluminum’s combination of thermal conductivity, extrudability, corrosion resistance, and compatibility with anodizing makes it an optimal choice for efficient, durable, and versatile heat sink solutions.