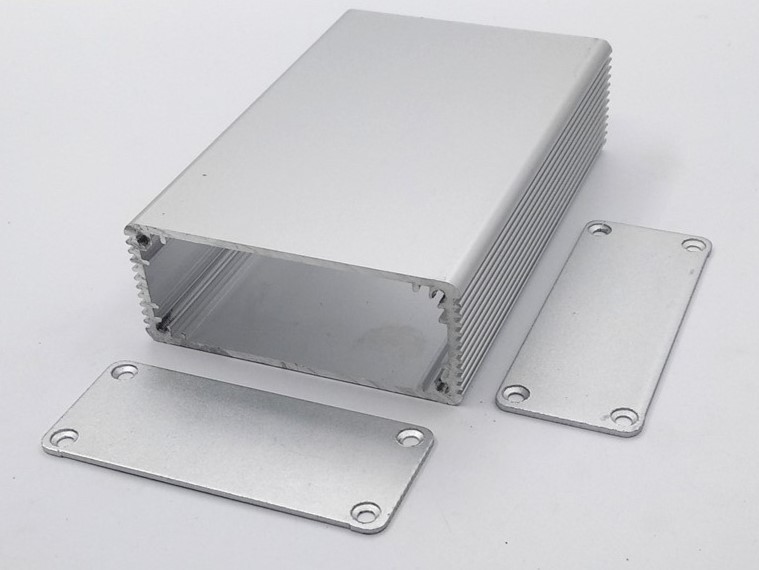

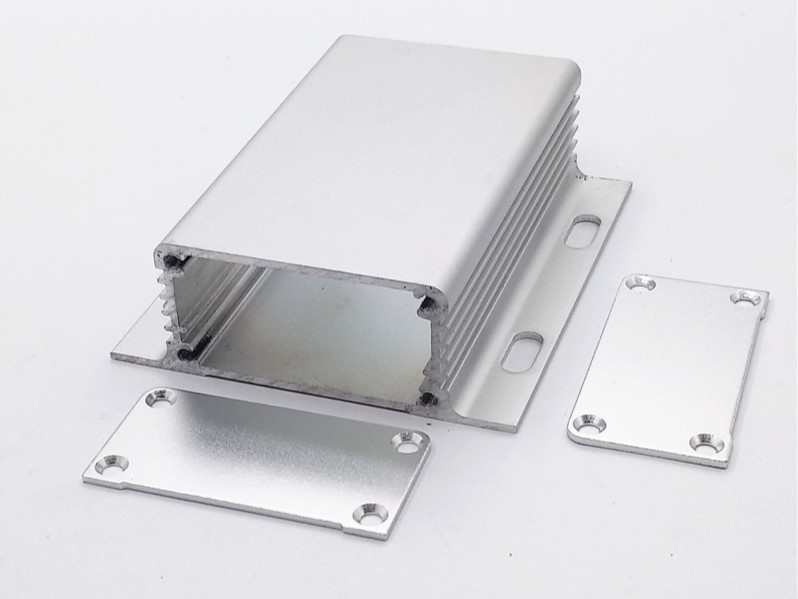

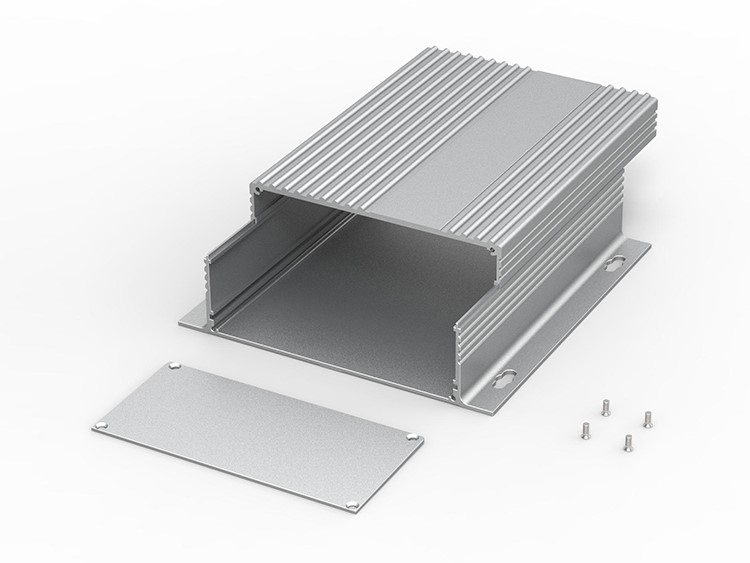

Extruded Aluminum enclosure

Precision-Engineered for Electronic Devices and Systems

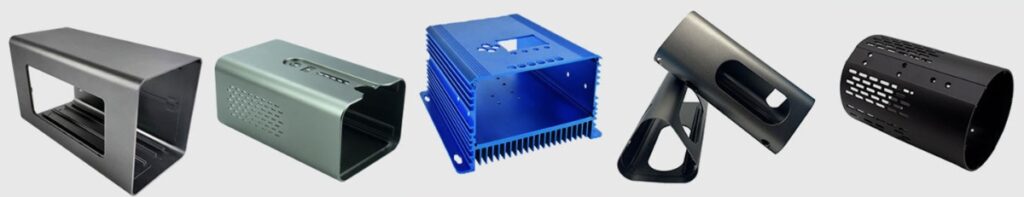

Aluminum Enclosures for Electronics and Industrial Applications

Our custom aluminum enclosures are designed to provide robust protection for sensitive electronics and industrial equipment, offering a durable, lightweight, and corrosion-resistant solution tailored to your specific project needs.

4 types of extruded aluminum enclosures

What is the best aluminum for enclosures?

The best aluminum material for enclosures typically depends on the specific application, but some of the most commonly used aluminum alloys for enclosures are:

6061 Aluminum

Properties: 6061 is one of the most versatile and widely used aluminum alloys. It offers excellent corrosion resistance, good mechanical properties, and high strength.

Best For: Enclosures that require durability, strength, and resistance to environmental factors, such as industrial, automotive, and outdoor applications.

Advantages: Strong, weldable, and suitable for both structural and aesthetic applications.

6063 Aluminum

Properties: Known for its excellent surface finish, 6063 aluminum is commonly used for extrusion. It offers good corrosion resistance, medium strength, and great formability.

Best For: Enclosures where appearance and ease of fabrication are key, such as electronics or architectural applications.

Advantages: Ideal for anodizing and provides a smooth, aesthetically pleasing finish.

7075 Aluminum

Properties: One of the strongest aluminum alloys, 7075 offers exceptional strength and hardness, but with lower corrosion resistance compared to 6061 and 6063.

Best For: Enclosures where high strength and weight reduction are critical, such as in aerospace or defense applications.

Advantages: Excellent strength-to-weight ratio, making it ideal for demanding, lightweight applications.

For general-purpose enclosures, 6061 is often the best choice due to its balance of strength, corrosion resistance, and affordability. For applications requiring a smooth finish and aesthetic appeal, 6063 is ideal. The right material choice depends on the specific demands of the enclosure’s application—strength, corrosion resistance, appearance, or weight may guide the decision.

Customized services for aluminum enclosure