Aluminum Chassis

Precision-Engineered for Electronic Devices and Systems

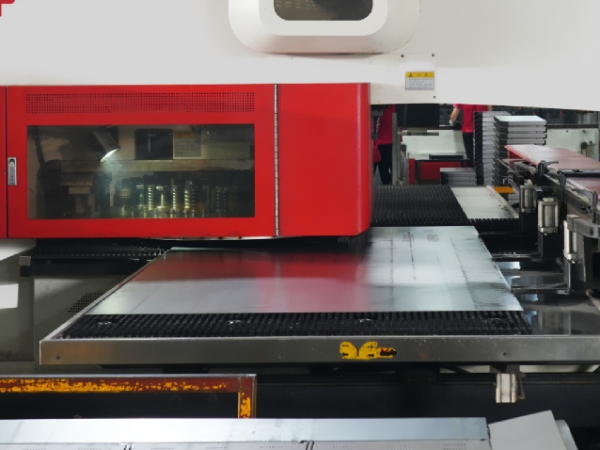

Sheet Metal Chassis & Housing Products

Fusionl Aluminum specializes in delivering custom aluminum chassis solutions designed to meet the unique requirements of a wide range of industries. With a strong focus on precision, quality, and innovation, we provide end-to-end manufacturing services to bring your designs to life.

Process and services for aluminum enclosure

We offer a comprehensive production process for custom aluminum products, ensuring precision, quality, and a flawless finish. Our streamlined process includes the following steps: