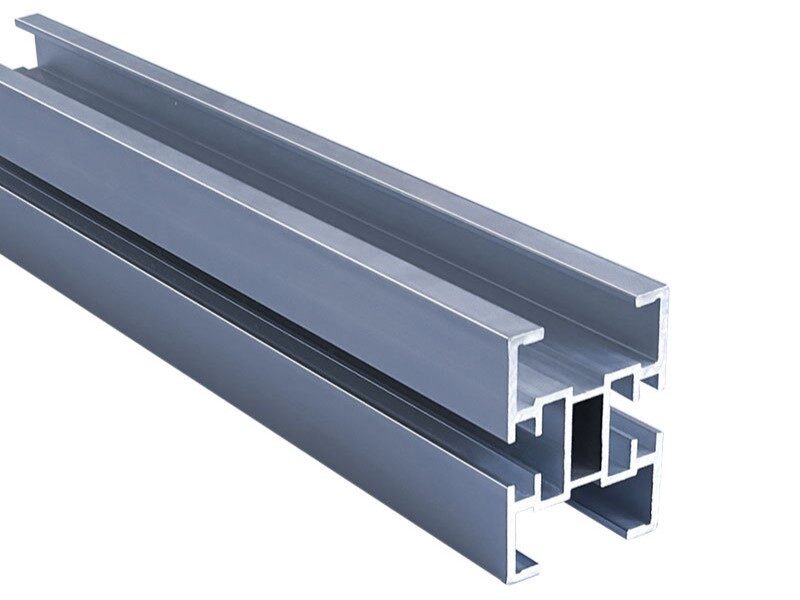

Aluminum beam

Low MOQ

Start your project with a small minimum order, reducing your upfront costs and risk.

Fast Lead Time

1-2 weeks for tooling time. Quickly bring your designs to life and shorten your product launch timeline.

Engineering Support

Translating complex design requirements into workable molds and extrusions.

CNC Fabrication

Cutting, CNC turning, precision CNC milling, bending, welding, and assembly.

Aluminum Beam Manufacturer

At Fusion Aluminum, we are a leading aluminum beam manufacturer, providing high-performance aluminum beams for various structural and industrial applications. With years of expertise in aluminum extrusion, we deliver superior products that combine strength, durability, and lightweight efficiency.

Aluminum i beam

Made from premium aluminum alloys such as 6061 and 6063, our I-beams provide excellent strength-to-weight ratios, ensuring stability and durability in structural applications.

Aluminum shoring beam

High-performance aluminum shoring beams are designed to offer superior strength and lightweight efficiency for load-bearing and support applications.

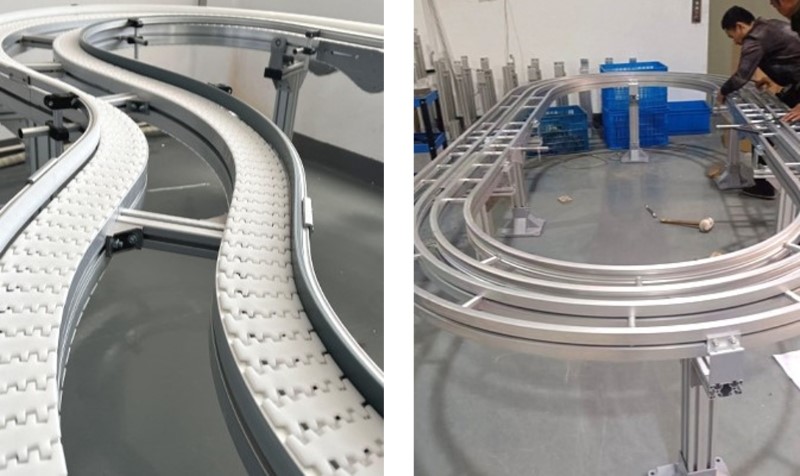

Conveyor beam

Durable and versatile conveyor beams, designed to provide reliable support for conveyor systems in manufacturing, logistics, and automation environments.

custom aluminum beams

Custom aluminum beams are tailored to meet the unique needs of your structural and industrial projects.

What is the use of aluminum i beams?

Aluminum I-beams are used in a variety of structural and industrial applications due to their excellent strength-to-weight ratio, corrosion resistance, and durability. Some of the key uses of aluminum I-beams include:

1. Construction and Building Frameworks:

Aluminum I-beams are often used in the construction of buildings, bridges, and infrastructure projects where lightweight yet strong support structures are required.

2. Industrial Machinery and Equipment:

They are used to build the structural frames of machines, conveyors, and support systems in industrial settings due to their strength and ability to withstand heavy loads while being lighter than steel.

3. Marine Applications:

Aluminum I-beams are ideal for marine environments, such as building boat docks, piers, and marine structures, due to their corrosion resistance, especially in saltwater environments.

4. Transportation (Automotive, Aerospace, and Rail):

Aluminum I-beams are used in the construction of lightweight vehicle frames, truck bodies, trailers, and even aircraft due to their ability to reduce weight without compromising structural integrity.

5. Solar Panel Mounting Systems:

In solar power installations, aluminum I-beams provide strong and lightweight support structures for solar panels, ensuring durability and long-term performance in outdoor environments.

6. Architectural and Decorative Projects:

Aluminum I-beams are also used in modern architectural projects for aesthetic and functional purposes, offering sleek designs that add visual appeal while maintaining structural strength.

7. Bridges and Walkways:

Used in pedestrian walkways, bridges, and platforms, aluminum I-beams provide durable support while reducing the overall load on the structure.

What are conveyor beams?

A conveyor beam is a structural component used to support and guide conveyor systems, which are used for transporting materials or products in industries such as manufacturing, logistics, and warehousing. The conveyor beam serves as the main frame or backbone of the conveyor, holding components like rollers, belts, chains, and motors in place.

Flexible conveyor system

conveyor aluminum beam

Fusion Aluminum: Leading aluminum beam manufacturer

At Fusion Aluminum, we are a leading aluminum beam manufacturer, providing high-performance aluminum beams for various structural and industrial applications. With years of expertise in aluminum extrusion, we deliver superior products that combine strength, durability, and lightweight efficiency.

Advanced Manufacturing: We use state-of-the-art aluminum extrusion technology to produce precisely engineered aluminum beams, ensuring high accuracy, quality, and consistency in every beam we manufacture.

High-Quality Materials: Our aluminum beams are made from top-grade aluminum alloys, such as 6061 and 6063, known for their excellent strength-to-weight ratio and corrosion resistance, making them ideal for indoor and outdoor use.

Custom Solutions: We specialize in custom aluminum beams, offering tailored solutions to meet the unique needs of your project. Whether you need specific sizes, profiles, or surface finishes, we deliver beams that perfectly fit your requirements.

Comprehensive Finishing Options: Our beams are available with a variety of surface finishes, including anodizing, powder coating, and brushing, providing both enhanced durability and aesthetic appeal.

Versatile Applications: Fusion Aluminum’s beams are used in construction, automotive, marine, industrial manufacturing, and many other industries, providing reliable support in both structural and non-structural applications.

As a trusted aluminum beam manufacturer, we are committed to delivering high-quality, innovative solutions that meet the demands of modern industries. Whether you’re looking for standard beams or fully customized profiles, Fusion Aluminum is your reliable partner for all your aluminum beam needs.

Why Choose Fusion Aluminum?

Low MOQ – only 500kg

Start your project with a small minimum order, reducing your upfront costs and risk.

1-2 weeks for mold development

Quickly bring your designs to life and shorten your product launch timeline.

2000+ standard molds

Save on mold costs by choosing from a wide selection of existing molds, speeding up production.

Fast response within 24 hours

Get the answers you need without delay, ensuring smooth communication and faster decision-making.