Aluminum handle profile

Low MOQ – 500Kg

Start your project with a small minimum order, reducing your upfront costs and risk.

Fast Lead Time

1-2 weeks for tooling time. Quickly bring your designs to life and shorten your product launch timeline.

Engineering Support

Translating complex design requirements into workable molds and extrusions.

CNC Fabrication

Cutting, CNC turning, precision CNC milling, bending, welding, and assembly.

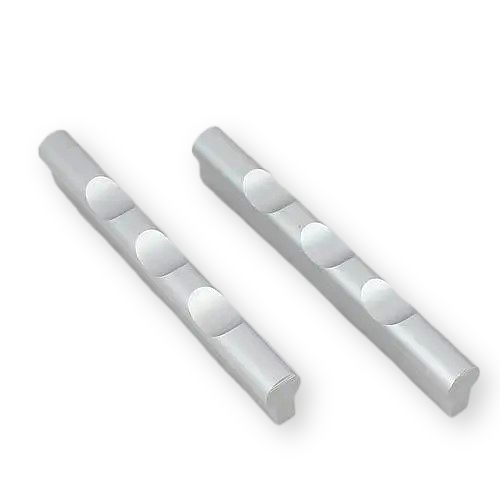

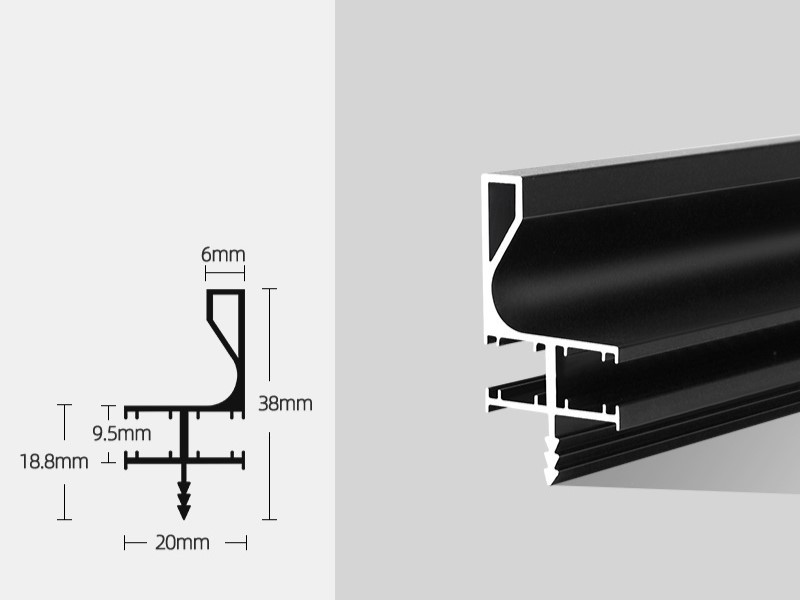

Custom Aluminum handle profile

Fusion Aluminum specializes in providing custom aluminum handle profiles to meet the unique needs of our clients. Our aluminum handles are not only lightweight and durable but also designed with precision to ensure high functionality and aesthetic appeal.

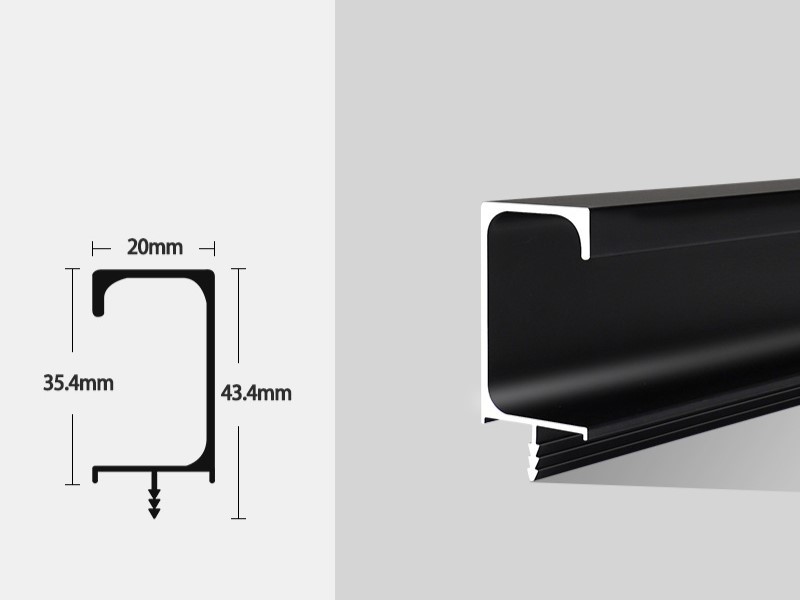

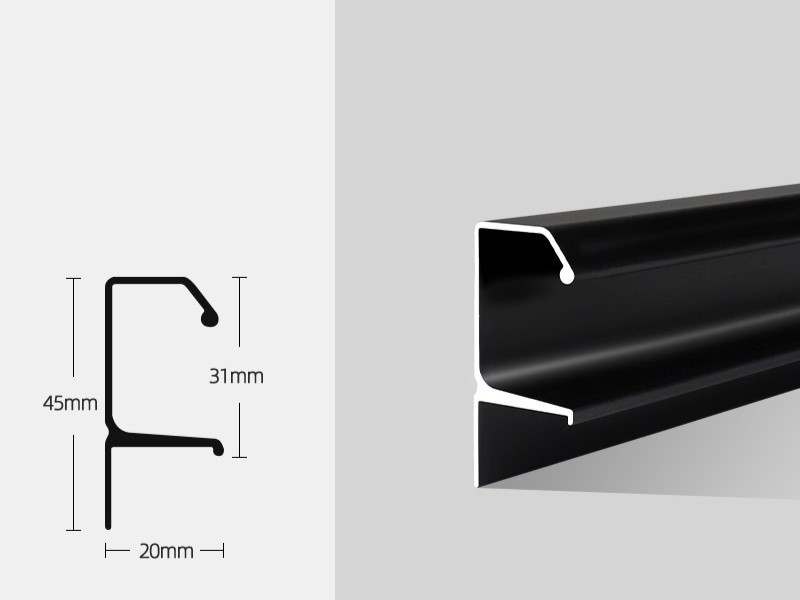

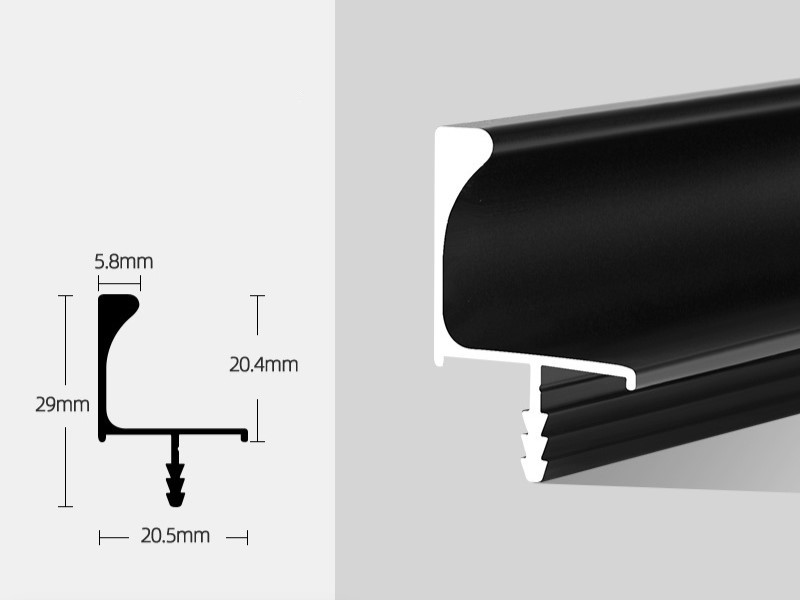

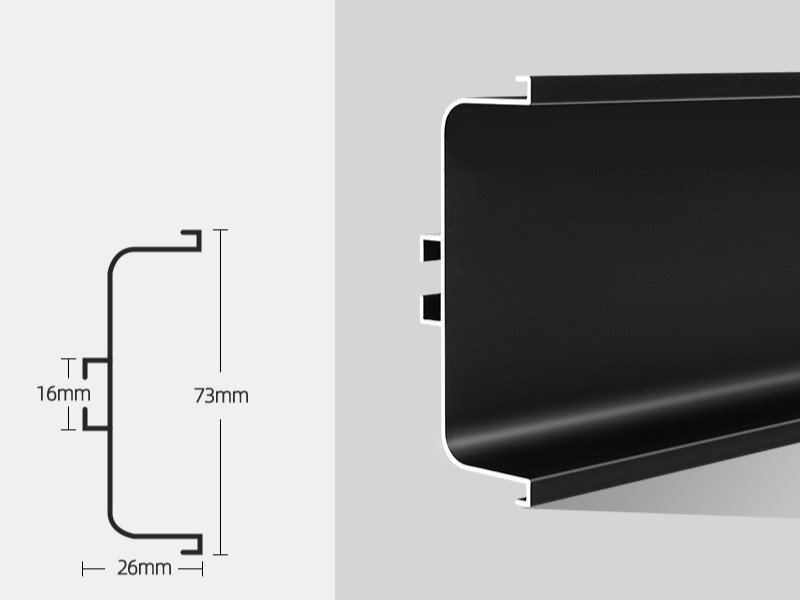

Aluminum G handle profile

Fusion Aluminum provides high-quality G handle profiles designed for modern furniture, like kitchen cabinets, and other applications requiring a sleek, integrated look.

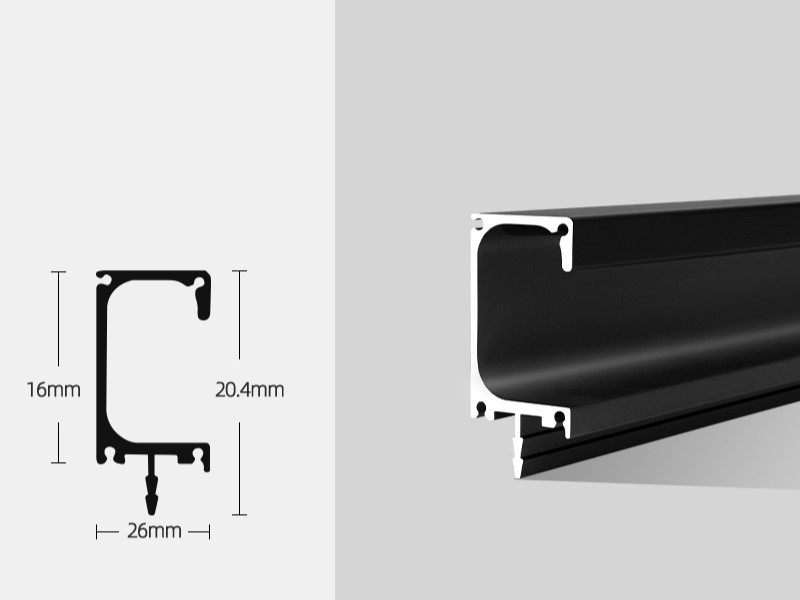

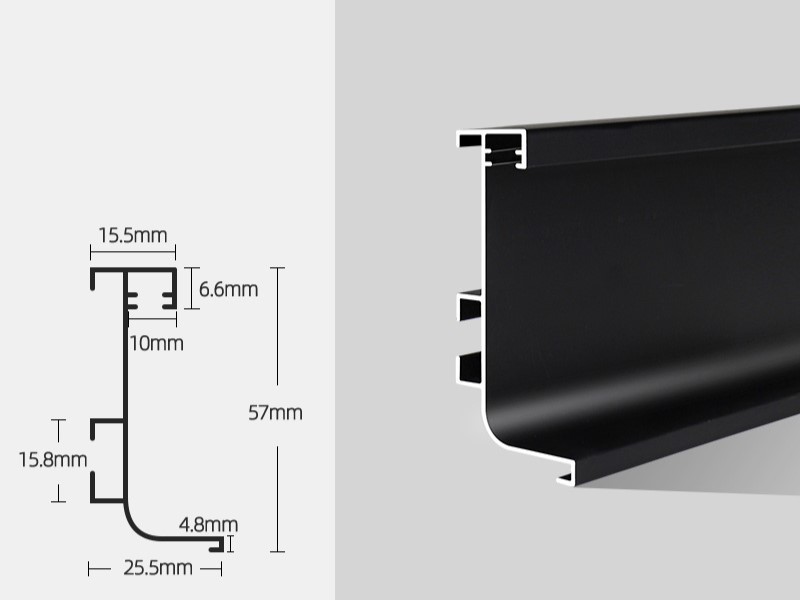

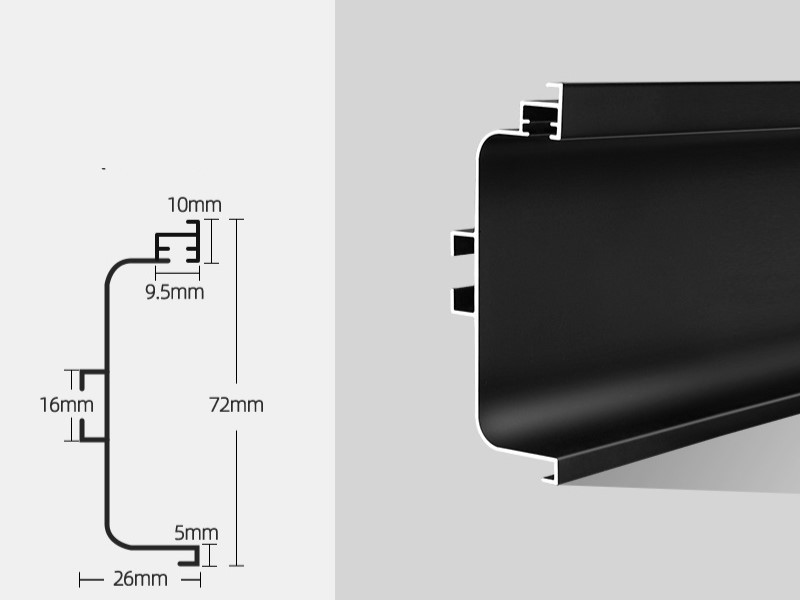

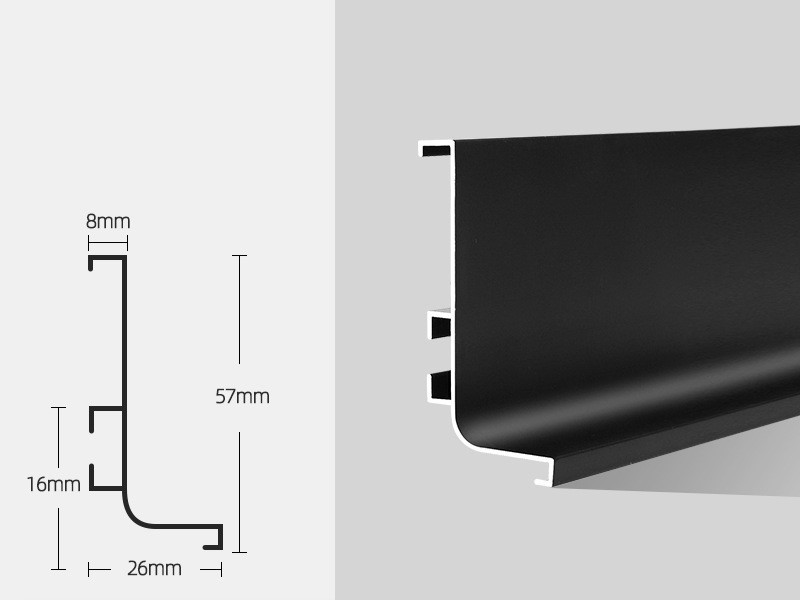

Aluminum Gola handle profile

High-quality Gola handle profile for modern furniture with a sleek and minimalist aesthetic.

What is a Gola handle profile?

Gola handle system is a type of handleless system usually used in modern kitchen and furniture design. Instead of traditional protruding handles, Gola handles are integrated into the cabinet structure, providing a sleek look. Gola system typically involves an aluminum handle profile, installed in the cabinet doors or drawers, allowing users to open them by gripping the edge. The below picture shows how a Gola handle works on a kitchen.

Gola handle profile sysytem

Is aluminum good for handles?

Aluminum alloy is an excellent choice for making handles due to its many advantages. Aluminum alloys (such as 6061, 6063, etc.) have low density, good mechanical properties, excellent machinability, high corrosion resistance, good electrical and thermal conductivity, and are easy to recycle. These characteristics make aluminum alloy handles lightweight, durable, and aesthetically appealing.

1. Lightweight

Aluminum alloy has a lower density, making aluminum handles lighter than traditional metal handles, which makes them easier to install and use.

2. High Strength

Despite being lightweight, aluminum alloy offers high strength and hardness, providing excellent durability and stability.

3. Corrosion resistance

The surface of aluminum alloy naturally forms a dense oxide layer, which protects the handle from corrosion and extends its lifespan.

4. Aesthetic appeal

Aluminum alloy can be processed through anodizing, sandblasting, brushing, and electroplating to achieve various colors and textures, meeting different design requirements.

5. Easy to manufacturing

Aluminum alloy is easy to shape and manufacture into various sizes and forms, allowing for custom handles to meet specific requirements.

6. Good thermal conductivity

Aluminum alloy is a good conductor of heat, enabling it to quickly dissipate heat from the handle, making it suitable for environments that require rapid cooling.

7. Recyclability

Aluminum alloy can be recycled and reused, contributing to environmental protection and aligning with sustainable development goals.

8. Wear resistance

Aluminum alloy handles have high surface hardness and good wear resistance, maintaining their appearance over time.

9. Cost-effective

Compared to materials like stainless steel or copper, aluminum alloy handles have lower costs, offering better value for money.

10. Good touch feel

The surface of aluminum alloy handles can be specially treated to provide a comfortable feel and a good gripping experience.

Why use extruded aluminum for handles?

Die-casting and extrusion are two common processes to make aluminum handles. Extruded aluminum is good for the minimalist-style handles. Die-casting aluminum is good for complex handle designs.

The tooling cost of extruded aluminum is cheaper than a die-casting mold. Usually, an extruded aluminum die costs $300, while a die-casting mold usually costs $3000. So extruded aluminum is friendly for small quantities.

Fusion Aluminum: Professional aluminum handle profile manufacturer

Fusion Aluminum has been producing aluminum handle profiles for more than 10 years. Our handle profiles are widely used in door handles, furniture handles, refrigerator handles, and oven handles. Our customers trust Fusion Aluminum because of bellows:

1. Good Aluminum material

At Fusion Aluminum, we only use fresh new aluminum material and never recycled aluminum material.

2. Custom services

We provide custom aluminum handle profile services. Most of our engineers have more than 10 years of experience in aluminum extrusion. We can help optimize the design of your product and develop molds.

3. Surface treatment

Fusion provides many different kinds of surface treatments for aluminum profiles, such as sandblasting, polishing, anodizing, wood texture, and powder coating.

4, Quality assurance

Fusion has a strict quality control process, from raw materials to each manufacturing process, ensuring every handle profile we produce meets high-quality standards.

5, Fast lead time

Fusion Aluminum owns 7 aluminum extrusion lines, and an in-house CNC workshop, we can be your one-stop partner for aluminum handle profiles.

6. In time response

Our account manager team always reply customer’s questions within 24 hours.

Send an inquiry

Why Choose Fusion Aluminum?

Low MOQ – only 500kg

Start your project with a small minimum order, reducing your upfront costs and risk.

1-2 weeks for mold development

Quickly bring your designs to life and shorten your product launch timeline.

2000+ standard molds

Save on mold costs by choosing from a wide selection of existing molds, speeding up production.

Fast response within 24 hours

Get the answers you need without delay, ensuring smooth communication and faster decision-making.