Why are heat sinks made of aluminum?

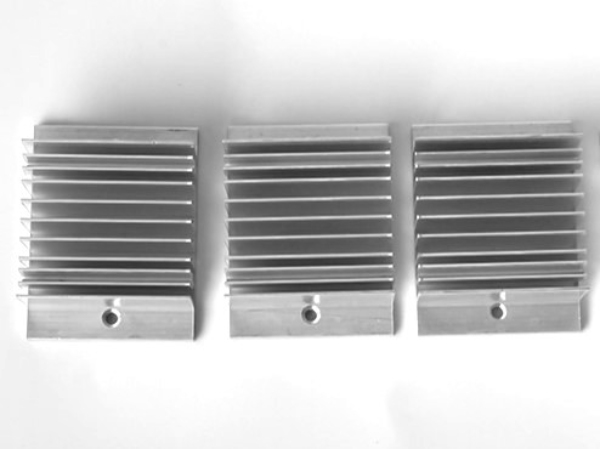

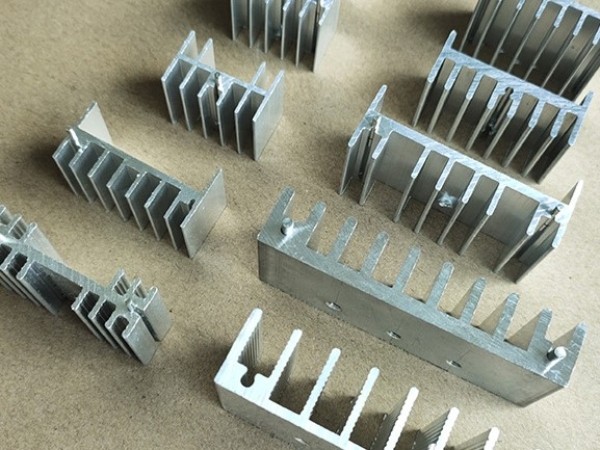

Aluminum extruded heat sinks are widely used in various fields due to their unique properties. The main reasons for using aluminum alloy to make radiators include the following:

Lightweight: Aluminum alloy has a low density, which allows the radiator to maintain good heat dissipation performance while reducing weight, making it easier to install and carry. When the heat dissipation is the same, the weight of the aluminum radiator is only one-eleventh of the cast iron radiator, one-sixth of the steel radiator, and one-third of the copper radiator.

Good thermal conductivity: Aluminum alloy has excellent thermal conductivity and can quickly transfer heat from the heat source to the surface of the radiator, thereby accelerating the dissipation of heat into the environment. Although the thermal conductivity coefficient of aluminum is lower than that of copper, its specific heat capacity is larger, which means that when absorbing the same amount of heat, the temperature of aluminum rises less, which helps to improve the heat dissipation efficiency.

Corrosion resistance and long service life: A solid oxide film can be formed on the surface of aluminum alloy materials, which makes aluminum alloy radiators have good corrosion resistance and can be used for a long time in various environments without rusting or oxidation.

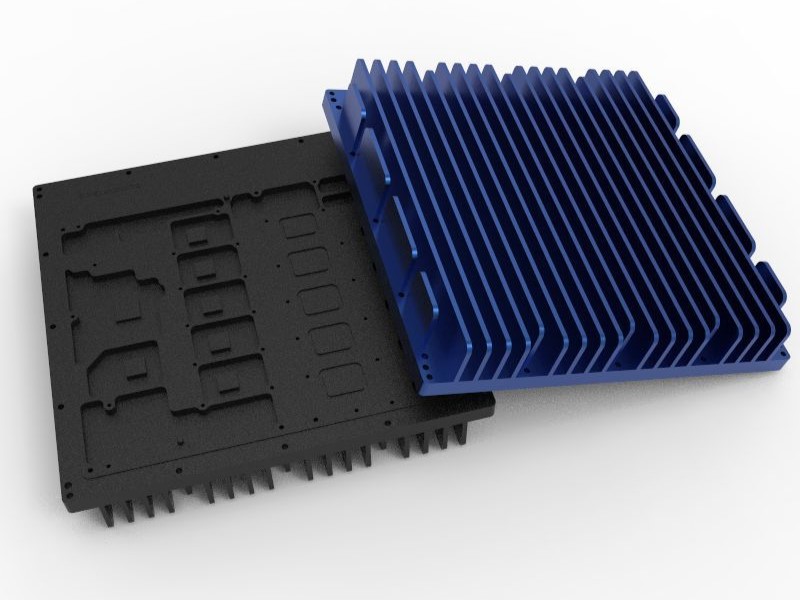

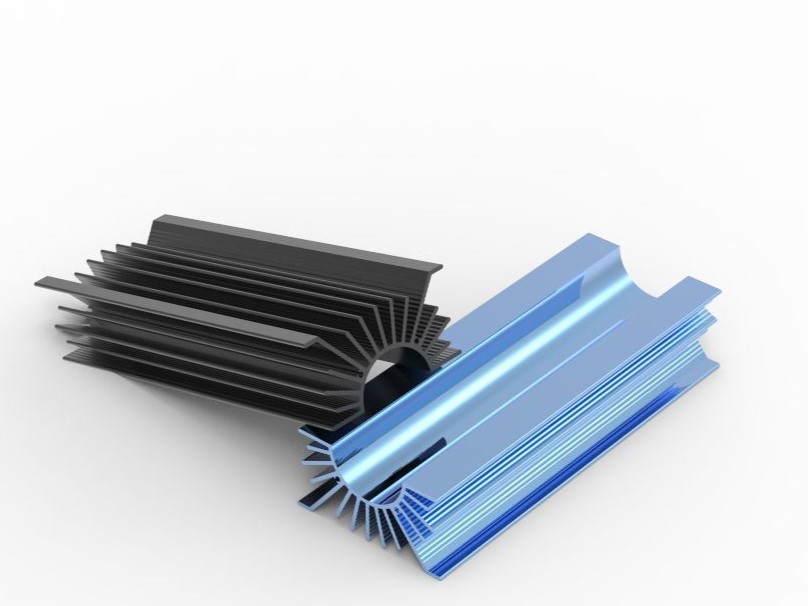

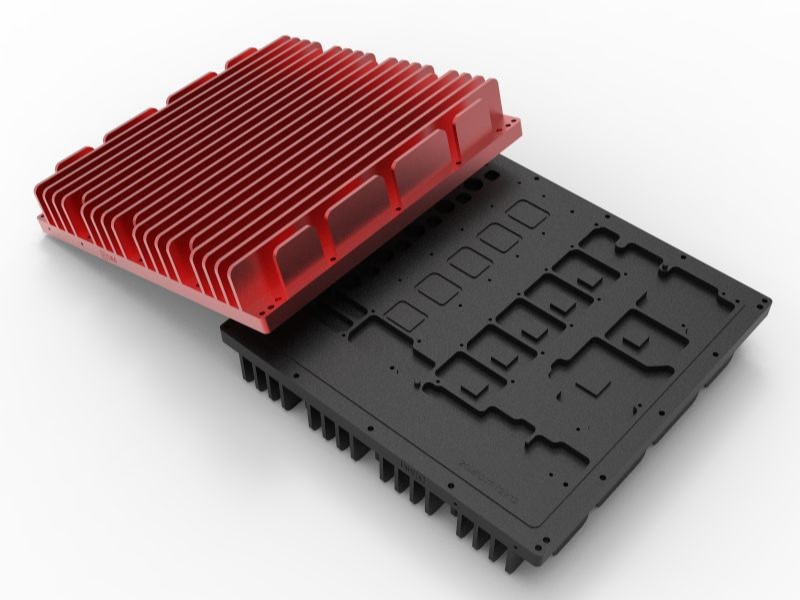

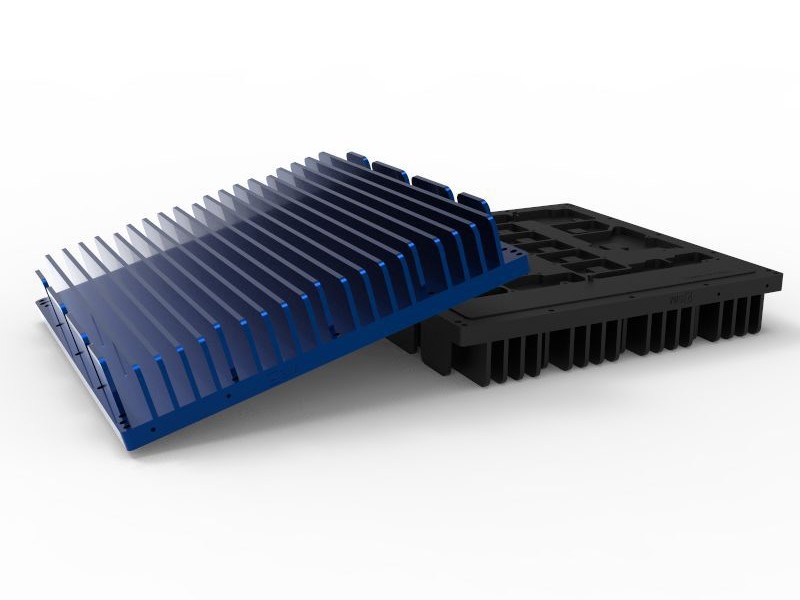

Simple manufacturing process: The production process of aluminum alloy radiators is relatively simple. They can be made into profiles of various shapes and specifications through processes such as extrusion. The production cost is low and they can be mass-produced.

Beautiful and durable: Aluminum alloy radiators can undergo a variety of surface treatments, such as anodizing, wire drawing, sandblasting, etc., which makes their appearance diverse, decorative, and durable.