Overview

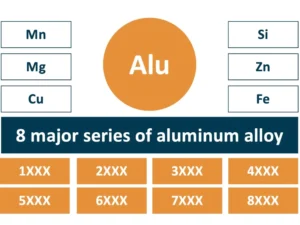

6061 aluminum is a heat-treatment-strengthened alloy with good formability, weldability, and machinability. It also has medium strength and can maintain good operability after annealing. The main alloying elements of 6061 aluminum are magnesium and silicon, forming Mg2Si phase. If it contains a certain amount of manganese and chromium, it can neutralize the bad effects of iron; sometimes a small amount of copper or zinc is added to improve the strength of the alloy without significantly reducing its corrosion resistance; there is also a small amount of copper in the conductive material to offset the adverse effects of titanium and iron on conductivity; zirconium or titanium can refine the grains and control the recrystallization structure; in order to improve the machinability, lead and bismuth can be added. When Mg2Si is solid-dissolved in aluminum, the alloy has artificial aging hardening function.

6061-T651 is the main alloy of 6061 aluminum alloy. Although its strength cannot be compared with 2XXX series or 7XXX series, it has many characteristics of magnesium and silicon alloys, such as excellent processing performance, excellent welding characteristics and electroplating properties, good corrosion resistance, high toughness and no deformation after processing, dense material without defects and easy to polish, easy to color film, and excellent oxidation effect.

6061 aluminum chemical composition

6061 aluminum alloy is part of 6000 aluminum alloy, its major elements alloying are magnesium and silicon. By adding magnesium and silicon, Mg2Si and Al3Mg2 can be formed in the alloy thereby allow aluminum alloys to be strengthened by heat treatment. In the table below you can find the main elements in 6061 aluminum.

| Element | Content |

|---|---|

| Magnesium, Mg | 0.8%~1.2% |

| Silicon, Si | 0.4%~0.8% |

| Chromium, Cr | 0.04%~0.35% |

| Copper, Cu | 0.15%~0.4% |

| Iron, Fe | <=0.7% |

| Manganese, Mn | <=0.15% |

| Titanium, Ti | <=0.15% |

| Zinc, Zn | <=0.25% |

| Others | each<=0.05%, total<=0.15% |

Material properties of 6061 aluminum

Density of 6061 aluminum

The density of 6061 aluminum is 2.7 g/cc in Metric and 0.0975 lb/in3 in English.

Mechanical properties of 6061 aluminum

| Property | 6061-T4 | 6061-T6 |

|---|---|---|

| Tensile strength | 241 Mpa / 35000 psi | 310 Mpa / 45000 psi |

| Yield strength | 145 Mpa / 21000 psi | 276 Mpa / 40000 psi |

| Modulus of Elasticity | 68.9 Gpa / 10000 ksi | 68.9 Gpa / 10000 ksi |

Thermal properties of 6061 aluminum

| Property | 6061-T4 | 6061-T6 |

|---|---|---|

| Coefficient of Thermal Expansion (20.0 – 100 °C Temp) | 23.6 µm/m-°C 13.1 µin/in-°F | 23.6 µm/m-°C 13.1 µin/in-°F |

| Thermal Conductivity | 154 W/m-K 1070 BTU-in/hr-ft²-°F | 167 W/m-K 1160 BTU-in/hr-ft²-°F |

| Melting Point | 582 – 651.7 °C 1080 – 1205 °F | 582 – 651.7 °C 1080 – 1205 °F |

Heat treatment of 6061 aluminum

The heat treatment process of 6061 aluminum material is divided into three steps:

Firstly, rapid annealing treatment involves heating the material to a temperature range of 350 ℃ to 410 ℃, and the holding time depends on the effective thickness of the material, generally between 30 minutes and 120 minutes. After annealing, air or water can be chosen for cooling.

Secondly, the high-temperature annealing step increases the temperature range to 350 ℃ to 500 ℃. For finished products with a thickness exceeding 6 millimeters, the insulation time is usually between 10 minutes and 30 minutes, while products with a thickness less than 6 millimeters require heat penetration. The cooling method also uses air cooling.

Finally, low-temperature annealing is performed, with the heating temperature controlled between 150 ℃ and 250 ℃. The insulation time is relatively longest, usually 2 to 3 hours. Similarly, air or water can be chosen for cooling to ensure the integrity of the heat treatment process.

The density of 6061 aluminum alloy is relatively low, at 2.7 g/cc, which also requires special attention during heat treatment to maintain the physical properties and structural stability of the material.

Corrosion resistance of 6061 aluminum

6061 aluminnum alloy has excellent corrosion resistance to atmospheric conditions and good corrosion resistance to seawater. This alloy also has a good finish and a good reaction to anodic oxidation. However, where appearance is crucial, consider using 6060 or 6063 alloy.

Weldability of 6061 aluminum alloy

The weldability of 6061 aluminum alloy is one of its standout features, making it a popular choice for structural and fabrication projects that require strong, reliable welds. As part of the 6000 series, 6061 aluminum is alloyed with magnesium and silicon, which contribute to its good weldability. Here are some key points about welding 6061 aluminum alloy:

1. Compatibility with Various Welding Methods: 6061 is compatible with TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding methods, which are commonly used for aluminum. These methods help ensure clean, strong welds that maintain the alloy’s structural integrity.

2. Heat-Affected Zone (HAZ): Like many aluminum alloys, 6061 can experience a reduction in strength in the heat-affected zone (HAZ) due to welding. However, this effect can often be mitigated by heat-treating the welded part after welding.

3. Filler Material Selection: Common filler materials, like 4043 or 5356 aluminum filler rods, work well with 6061. 4043 is preferred for applications requiring a smoother finish and lower sensitivity to cracking, while 5356 is typically used when a stronger weld is needed.

4. Anodizing After Welding: 6061 can be anodized post-welding to enhance its corrosion resistance and appearance, though it may show slight color variation between the weld area and the base material due to differences in composition.

Various standards of 6061 aluminum

| Grade | Standards | Country / Org |

|---|---|---|

| 6061 / A96061 | A.A / UNS | U.S.A |

| LD30 | GB/T 3190-2008 | China |

| AlMgSi1Cu/3.3211 | DIN 1725.1-1986/W-Nr | German |

| A6061 | JIS H4000-1999 JIS H4040-1999 | Japan |

| AlMg1SiCu | ISO 209.1-1989 | ISO |

| EN AW-6061/AlMg1SiCu | EN 573-3-1994 | EU |

| 65032 | IS 733-2001 IS 737-2001 | Indian |

| 6061(A-GSUC) | NF A50-411 NF A50-451 | France |

| 6061(N20/H20) | BS 1470-1988 | UK |

Applications of 6061 aluminum

Representative applications of 6061 aluminium alloy include aerospace and electrical fixtures, as well as communications. They are also widely used in automated machinery parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, etc.

Electronic home appliances: 6061 also used in various busbars, wiring, conductors, electrical components, refrigerators, air conditioners, cables and other fields.

Aerospace: 6061 aluminium alloy can be used to make aircraft skins, fuselage frames, beams, rotors, propellers, fuel tanks, siding and landing gear pillars, as well as rocket forging rings, spacecraft siding, etc.

Transportation: 6061 aluminium alloy also used for car, subway car, railway passenger car, high-speed passenger car body structural materials, doors and windows, shelves, automotive engine parts, air conditioners, radiators, body panels, wheels and ship materials.

Packaging: Aluminum alloy 6061 is also used as metal packaging materials in the form of thin plates and foils, made into cans, lids, bottles, barrels, packaging foils, which are widely used in packaging of beverages, food, cosmetics, medicines, cigarettes, industrial products, etc.

Printing: Mainly used to make PS plates. Aluminum-based PS plates are a new type of material for the printing industry. They are used for automatic plate making and printing.

Architectural decoration: alloy 6061 is mainly used in building frames, doors and windows, suspended ceilings, metal curtains, perforated metal sheet, decorative surfaces, etc. Such as various architectural doors and windows, aluminum profiles for curtain walls, aluminum curtain wall panels, profiled panels, checkered panels, color coated aluminum panels, etc.